Alternative Energies

See other Alternative Energies Articles

Title: Audi creates green 'e-diesel fuel of the future' using just carbon dioxide and water

Source:

International Business Times, UK

URL Source: http://www.ibtimes.co.uk/audi-creat ... t-carbon-dioxide-water-1498524

Published: Apr 27, 2015

Author: Ewan Palmer

Post Date: 2015-04-27 10:34:58 by Tooconservative

Keywords: None

Views: 13256

Comments: 26

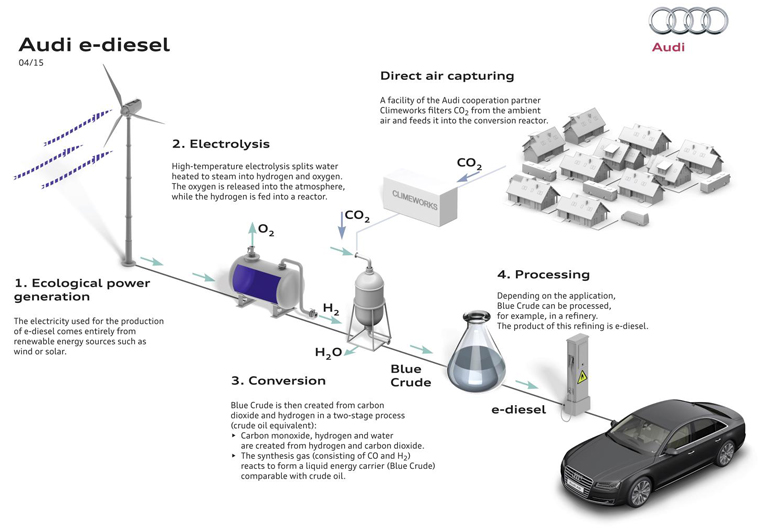

German car manufacturer Audi says it has created the "fuel of the future" made solely from water, carbon dioxide and renewable sources. The synthetic "e-diesel" was made following a commissioning phase of just four months at a plant in Dresden, Germany. Unlike regular diesel, the clear fuel does not contain any sulphur or fossil oil, while it has an overall energy efficiency of around 70%. Germany's federal minister of education and research, Dr Johanna Wanka, said she has already used the fuel in her Audi A8, while the company hopes the Dresden factory, operated by clean tech company Sunfire, will produce 160 litres of it every day in the coming months. "This synthetic diesel, made using CO2, is a huge success for our sustainability research," Wanka said. "If we can make widespread use of CO2 as a raw material, we will make a crucial contribution to climate protection and the efficient use of resources, and put the fundamentals of the 'green economy' in place." Creation of the fuel, which Audi and Sunfire are calling blue crude, first requires heating water to 800C (1,472F) to trigger a high temperature electrolysis to break down the steam to hydrogen and oxygen. The hydrogen then reacts with the CO2 in synthesis reactors, again under pressure and at a high temperature. The reaction product is a liquid made from long‑chain hydrocarbon compounds, known as blue crude. This synthetic fuel, which is free from sulphur and aromatic hydrocarbons, is suitable for mixing with fossil diesel or being used as a fuel in its own right. Reiner Mangold, head of sustainable product development at Audi, said: "In developing Audi e-diesel we are promoting another fuel-based on CO2 that will allow long‑distance mobility with virtually no impact on the climate. Using CO2 as a raw material represents an opportunity not just for the automotive industry in Germany, but also to transfer the principle to other sectors and countries." Poster Comment: One of a number of promising alt energy technologies on the horizon.

Post Comment Private Reply Ignore Thread

Top • Page Up • Full Thread • Page Down • Bottom/Latest

#1. To: TooConservative (#0)

(Edited)

Only one small problem. The exhaust is hydrogen cyanide. Oh, those German engineers.

And at enormous cost to produce.

Oh God, not this old and very tired Fischer-Tropsch technology BS again. The world seems to be full of idiots.

потому что Бог хочет это тот путь

This is different. F-T maxed out at 700°F. This process runs to 1400° for the hydrolysis. I assume they've changed the catalyst type as well. So this is not your daddy's F-T process.

Hey, boys and girls, there is CO2 and H2O in air and air powers wind turbines. Hell, we can make diesel fuel out of nothing but air. Ain't that sumtin? Whodathunkit?

потому что Бог хочет это тот путь

Oh, those German engineers. Witty. They could call their cars Zyklonmobiles and drive them through Jewish neighborhoods. These old jokes never gets old apparently.

Go get 'em, Champ.

потому что Бог хочет это тот путь

Since you are hungry to learn more: 14 November 2014 Audi is active in the development of CO2-neutral, synthetic fuels; the company already has projects underway with Joule in the US for the development and testing of synthetic ethanol and synthetic diesel (earlier post); has an e-gas project underway in Werlte, Germany (earlier post); and has a new partnership with Global Bioenergies on bio-isooctane (bio-gasoline) (earlier post). Audi’s latest e-fuels project is participation in a a pilot plant project in Dresden that produces diesel fuel from water, CO2 and green electricity. Audi and project partners including Climeworks and sunfire (earlier post) opened the plant today. The project combines two innovative technologies in this project, which is funded in part by the German Federal Ministry for Education and Research and was preceded by a two-year research and preparation phase: direct capture of CO2 from ambient air and a power‑to‑liquid process for the production of synthetic fuel. Audi is the exclusive partner in the automotive industry. Other partners in the project consortium include Lufthansa; Fraunhofer ICT; Universität Stuttgart; Forschungszentrum Jülich; GEWI AG; CVT Chemical Engineering; and HGM. The sunfire plant, which operates according to the “power-to-liquid” (PtL) principle, requires carbon dioxide, water and electricity as raw materials. The carbon dioxide is extracted directly from the ambient air using direct air capture (DAC)—a technology developed by Swiss partner Climeworks. The Climeworks CO2 capture technology is based on a cyclic adsorption / desorption process on a novel sorbent. During adsorption, atmospheric CO2 is chemically bound to the sorbent’s surface. Once the sorbent is saturated, the CO2 is driven off the sorbent by heating it to 95 °C, thereby delivering high-purity gaseous CO2. The CO2-free sorbent can be re-used for many adsorption/desorption cycles. Around 90% of the energy demand can be supplied by low-temperature heat; the remaining energy is required in the form of electricity for pumping and control purposes. The patent-pending technology has been developed in collaboration with the Professorship of Renewable Energy Carriers at ETH Zurich. The optimization of the sorbent and scale-up of the sorbent synthesis process is carried out in collaboration with the Swiss Laboratories for Materials Science and Technology (Empa). In a separate process, a solid oxide electrolysis (SOEC) unit powered with green electricity splits water into hydrogen and oxygen. (sunfire acquired staxera, a developer and manufacturer of SOFC high-temperature fuel cells sited in Dresden in 2011.) The hydrogen is then reacted with the carbon dioxide in two chemical processes conducted at 220 ÚC and a pressure of 25 bar to produce a hydrocarbon liquid called Blue Crude. The process is up to 70% efficient. As currently built, the pilot plant on the sunfire grounds in Dresden-Reick can produce approximately 160 liters of Blue Crude per day. Nearly 80% of that can be converted into synthetic diesel. This fuel—Audi e‑diesel—is free of sulfur and aromatics, and features a high cetane number. Its chemical properties allow it to be blended in any ratio with fossil diesel—i.e., it can be used as a drop-in fuel. The Audi e‑gas plant in Werlte, Lower Saxony, already produces synthetic methane (Audi e‑gas) in a comparable manner; drivers of the Audi A3 Sportback g‑tron can fill up on it using a special fuel card. (Earlier post.) Audi is also conducting joint research into the synthetic manufacture of Audi e‑gasoline with Global Bioenergies. And a joint project with Joule is striving to produce the synthetic fuels Audi e-diesel and Audi e‑ethanol with the help of microorganisms. With this latest collaboration, Audi said, it and its partners are demonstrating that industrialization of e‑fuels is possible. The pilot plant was officially brought on stream today in the presence of Prof. Dr. Johanna Wanka, German Federal Minister for Education and Research, and Dr. Hagen Seifert, Head of Environmental Assessments, Renewable Energies and New Materials at Audi AG. Stated more bluntly elsewhere: An Audi facility in Dresden began making a small amount of the "e-diesel" this month. Writes Science Alert: "The first step involves harvesting renewable energy from sources such as wind, solar and hydropower. They then use this energy to split water into oxygen and pure hydrogen, using a process known as reversible electrolysis. This hydrogen is then mixed with carbon monoxide (CO), which is created from carbon dioxide (CO2) that's been harvested from the atmosphere. The two react at high temperatures and under pressure, resulting in the production of the long-chain hydrocarbon compounds that make up the blue crude." So, yes, as you said, clean diesel from air and water.

The hydrogen then reacts with the CO2 in synthesis reactors, again under pressure and at a high temperature. The reaction product is a liquid made from long‑chain hydrocarbon compounds, known as blue crude. This process runs to 1400° for the hydrolysis. Sorry to break it to you, I was going to let it slide but thought naw. The hydroloysis part of the process chain is not F-T technology. F-T is the conversion of CO2 and H2 into liguid fuesl. This is what the Germans were forced to use in WWII and the South Africans when the world boycotted them. It is very old and very expensive technology that keeps getting recycled over and over and over again as the answer to the world's energy needs. My junior year HS organic chemistry class final (circa 1960) had five problems each stated as follows: Starting with coal, air and water synthesize .......... I got a 100%. Actually it is theoretical quite easy to do. Elimianting what essentially are feedstock concentration steps, all you need to do is partially burn coal in air to produce CO. Use the Water Shift reaction to convert CO and H2O to CO2 and H2 and then use F-T to produce longer chain hydrocarbon compounds. If money is no object, voila you have lquid hydrocarbon fuesl made from nothing but coal, air and water. Neat, no? So ask yourself this, why isn't anyone doing this? Knock yourself out if you don't have a better waste of your time.

потому что Бог хочет это тот путь

Just so long as they consist of lima beans. We'll use another renewable resource. Really. (LOL)

70 percent efficient? YIKES!

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

I love lima beans. Maybe you don't know how to prepare them properly. Most people cook them into a repellant mush.

As long as you're around, I don't need a waste of time. Which is why they don't bother to call this F-T. There are a number of new subsystems in this process, no matter how much you love reliving the glory days of SoSo, Boy Genius back in 1960.

Boy, it really bothers you when I reveal your ignorance. However this is only slightly more fun than pulling the wings off of flies. And yes, I was a boy genius back in 1960 but only one of many in my class and my school. That must piss you off even more. "Which is why they don't bother to call this F-T." And dupes such as you fall for the ploy. Knock youself out.

потому что Бог хочет это тот путь

Yes, that is exactly what they are. Except for the lima bean, bacon and carrot casserole

YIKES! So that means were looking at what about 2 gallons per mile of driving? Hell you might as well get out and push the damn thing.

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

YIKES! So that means were looking at what about 2 gallons per mile of driving? What are you talking about? That is more efficient than either gasoline or diesel.

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

I was kidding. In my career field (HVAC) 70% efficiency was 50 years ago or so. You can get natural gas furnaces as efficient as 98% nowadays, they will cost you but they are available. The problem with them is if something goes wrong it will cost you an arm and a leg to get it fixed. I "wouldn't" recommend anything over 92% because they are still reasonable to install and repair.

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

I didn't know that. I had a 250k Modine forced air furnace put in my shop last fall,and it was supposed to be one of the most efficient,and was only somewhere in the 80's. Mostly because it was vented. Mine burns propane because I can't get NG where I live,but I doubt there is that much,if any,difference in the efficiency. I will say this. Once that thing gets wound up it doesn't take but a few minutes to get to t-shirt temps in the shop.

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

Provided that 1 cubic foot of propane contains 2,516 BTU and 1 cubic foot of natural gas contains 1,030 BTU, it is accurate to say that propane contains over twice the usable energy content per cubic foot (2.44 times more). In fact when it gets really cold they inject Propane into the NG lines to help out. It's kinda like burning wood, some woods burn up in no time and others like Ash burns for a really long time, more bang/BTUs for the buck or should I say more bang for the tree!!

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

That one only has 1 heat exchanger in it while some of the Ultra high efficiency ones use 2 heat exchangers and multiple speed fans. They are also vented but the percentage that goes up the flue is much less, as you can see.

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

That's not bad for one of those hanging unit heaters, they used to be much worse efficiency wise.

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

I had no idea. All the local "experts" keep telling me "ya shudda got NG!" Yeah,I shudda been born wealthy too,but that didn't happen either.

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

SOB puts out some serious BTU's. The day the electrician got it wired and we turned it on,the daytime temps were in the low 30's,and it was actually painful to touch the fender of my 31 Plymouth sitting under my life,or to touch one of the lift supports. Within 15 minutes both were warm to the touch,and radiating heat. I do know I need to sell something this summer to come up with the cash to get insulation sprayed on my shop walls because I can't afford another winter buying that much propane,just to keep it in the low 50's inside. Does ok in the daytime because the steel walls radiate heat from the sun,but once the sun goes down the propane starts rolling.

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

Yes you do need to get some insulation in there that would help immensely. But even a lot of insulation won't help if you have high ceilings, that's where all your heat goes cause heat rises. My guess is that Modine is mounted at least 6-8 feet off the ground so the only way for the heat to get to ground level is if the fan in the heater is strong enough to get it there. But it doesn't stay there very long cause heat rises and cold air sinks, a quandary ehhh but a somewhat fixable quandary. What you could do to help out is install a couple of 60" or larger residential ceiling fans to pull the heat from the peak and send it down to the floor. When I first picked up the Montgomery Cty Water and Waste Treatment Plant they were having issues with it getting too cold in one of the pump buildings. This building was well insulated and had 15-18' ceiling in it and the heater was mounted up about 12' high on one wall. They were convinced there was something wrong with the heater when there wasn't, just a simple physics issue "Heat rises and cold sinks". They had a one man lift in there so I told the customer to take the lift up near the ceiling and tell me what he felt. He got up within 6' or so of the ceiling and said "Damn it's getting hot up here", then he said "there ain't nothing wrong with the heater all the heat is just rising"... (Duhhhhh)... So I proposed putting in three 60" residential ceiling fans dropped down about 6-8' on rods to push the heat down from the ceiling to the floor where all the pumps where. Also made them thermostat controllable and mounted the stat about 2' off the floor instead of the usual 5' high. Worked like a charm brought the temp down at floor level up about 15-20 degrees and the customer was happier than a pig in schitt. This all went down about 15 years ago and to this day the fans are still working beautifully. Albeit they need to have the blades cleaned every few years so they don't get off balance and ruin the bearings. There is another solution but it would be more expensive and that would be installing some infrared type tube heaters and have certain areas of the shop be warm and others well who cares. http://www.globalindustrial.com/p/hvac/heaters/gas-infrared/propane-heater- infrared-tube-125000-btu-40l? infoParam.campaignId=T9F&gclid=CP24vo7uncUCFQEGaQodJnYAqQ They are mounted overhead in certain areas of the shop/building and have a reflector on top to reflect the heat downwards, but they are intended to warm up surfaces more than designed to warm up the whole shop. Now I have seen them used to warm up the whole shop but the bill for gas is astronomical. There is also a vertical type of infrared they use to warm up people sitting on decks or patios but I haven't really had any experience with them so don't know what to tell you about them.. http://www.mycoolingstore.com/commercial-stainless-steel-glass-tube-patio- heater.html#.VUILQ2DwuM8 Hope this helps pete, anyway gotta go jump in the shower and head off to work.

“Political correctness is a doctrine, fostered by a delusional, illogical minority, and rapidly promoted by mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end.”

My ceiling is 18 feet high in the shop part. My guess is that Modine is mounted at least 6-8 feet off the ground Closer to 12 feet. The roof of my "office" is close to 9 feet off the floor,and it's mounted above the flat office roof. The office is built inside the structure as a free-standing structure. so the only way for the heat to get to ground level is if the fan in the heater is strong enough to get it there. I have louvers on the front of the furnace,and you can feel the hit hitting you standing underneath the car lift. I have 7 cars inside the shop right now,plus maybe 4 tool boxes and shelves 4 high running 50 feet down one side and 30 feet down the other side that are loaded with steel and aluminum auto parts and tools. Plus stuff like my English Wheel,my sheet metal brakes,etc,etc,etc that are sitting on the floor. All that stuff gets warm pretty quickly and helps warm the floor area via radiation. Also,there is a plastic insulation pad beneath the cement floor that helps keep the floor from getting so cold. I built my 9x20 "office/bathroom" from 2x6's with half inch plywood walls inside and out,and insulated it with R-19. I can pretty much heat that with a candle since it sits inside the big building and gets no wind or outside temperature exposure. I've thought about your ceiling fan solution,but pretty much dismissed it after installing ac early last summer. I had been using a attic fan rated at handling around 1600 sq feet in each end of the building and on opposite sides to get the air moving inside and to exhaust the humidity,and had been worried about my electric bill climbing after installing the ac units. Damned if it didn't drop. It was cheaper to cool it with AC than it was to run exhaust fans out the gable ends. Plus it is a workshop,and I really don't want it to get over 60F in there in the winter unless I am doing body work and painting. When I'm doing mechanical work I like to keep it cool enough I can wear a long sleeved shirt or a hoodie so I can protect my arms and head from debris without sweating. To me,60-65 degrees is a perfect inside temperature for working. The big propane expense comes from heating all those cars and the other steel inside. Yeah,they heat easily,but they also get cold easily when the sun goes down and the steel building is leaking heat instead of radiating it. I'm thinking this won't be a problem once I get the insulation sprayed in. I'm even thinking about spraying it over my sun lights in the roof,but I really hate the idea of turning the place into a dark cave. I have been thinking of building a sliding skylight cover that I can open and close with a remote so I have sunlight in the day,and can close it up at night so the heat doesn't escape. Probably won't do it because I am not as agile as I used to be,and have no business climbing up that high.

Why is democracy held in such high esteem when it’s the enemy of the minority and makes all rights relative to the dictates of the majority? (Ron Paul,2012)

"German car manufacturer Audi says it has created the "fuel of the future" made solely from water, carbon dioxide and renewable sources."

#2. To: misterwhite (#1)

#3. To: TooConservative, All (#0)

#4. To: SOSO (#3)

Oh God, not this old and very tired Fischer-Tropsch technology BS again. The world seems to be full of idiots.

#5. To: TooConservative, All (#0)

German car manufacturer Audi says it has created the "fuel of the future" made solely from water, carbon dioxide and renewable sources.

#6. To: misterwhite (#1)

Only one small problem. The exhaust is hydrogen cyanide.

#7. To: TooConservative (#4)

So this is not your daddy's F-T process.

#8. To: SOSO (#7)

Audi in new e-fuels project: synthetic diesel from water, air-captured CO2 and green electricity; “Blue Crude”

Top: Two cartoons of the basic sunfire concept and process. PtL = Power-to-Liquids. Bottom: 3D model of sunfire SOEC (left) and the demo plant (right). Source: sunfire. Click to enlarge.

#9. To: TooConservative, All (#6)

Creation of the fuel, which Audi and Sunfire are calling blue crude, first requires heating water to 800C (1,472F) to trigger a high temperature electrolysis to break down the steam to hydrogen and oxygen.

#10. To: TooConservative, rlk, SOSO (#0)

... renewable sources...

I hate those damn things. I have since I was 4 years old.

Quite frankly - the planet should be RID of them...

#11. To: TooConservative, *Science and technology*, *Gear Heads* (#0)

#12. To: Chuck_Wagon (#10)

Just so long as they consist of lima beans.

#13. To: SOSO (#9)

So ask yourself this, why isn't anyone doing this? Knock yourself out if you don't have a better waste of your time.

The hydroloysis part of the process chain is not F-T technology.

#14. To: TooConservative (#13)

There are a number of new subsystems in this process, no matter how much you love reliving the glory days of SoSo, Boy Genius back in 1960.

#15. To: TooConservative (#12)

...repellant...

that my late Aunt Mildred used to make.

They were almost edible that way.

#16. To: sneakypete (#11)

70 percent efficient?

#17. To: CZ82 (#16)

70 percent efficient?

#18. To: sneakypete (#17)

#19. To: CZ82 (#18)

You can get natural gas furnaces as efficient as 98% nowadays,

#20. To: sneakypete (#19)

Mine burns propane because I can't get NG where I live, but I doubt there is that much,if any,difference in the efficiency.

#21. To: sneakypete (#19)

I didn't know that. I had a 250k Modine forced air furnace put in my shop last fall,and it was supposed to be one of the most efficient,and was only somewhere in the 80's. Mostly because it was vented.

#22. To: sneakypete (#19)

#23. To: CZ82 (#20)

In fact when it gets really cold they inject Propane into the NG lines to help out.

#24. To: CZ82 (#22)

That's not bad for one of those hanging unit heaters, they used to be much worse efficiency wise.

#25. To: sneakypete (#24)

#26. To: CZ82 (#25)

Yes you do need to get some insulation in there that would help immensely. But even a lot of insulation won't help if you have high ceilings, that's where all your heat goes cause heat rises.

Top • Page Up • Full Thread • Page Down • Bottom/Latest

[Home] [Headlines] [Latest Articles] [Latest Comments] [Post] [Mail] [Sign-in] [Setup] [Help] [Register]